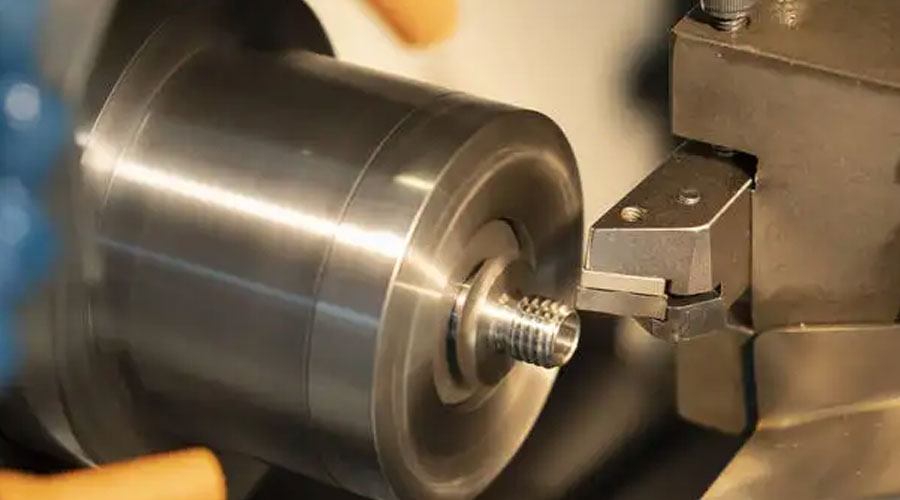

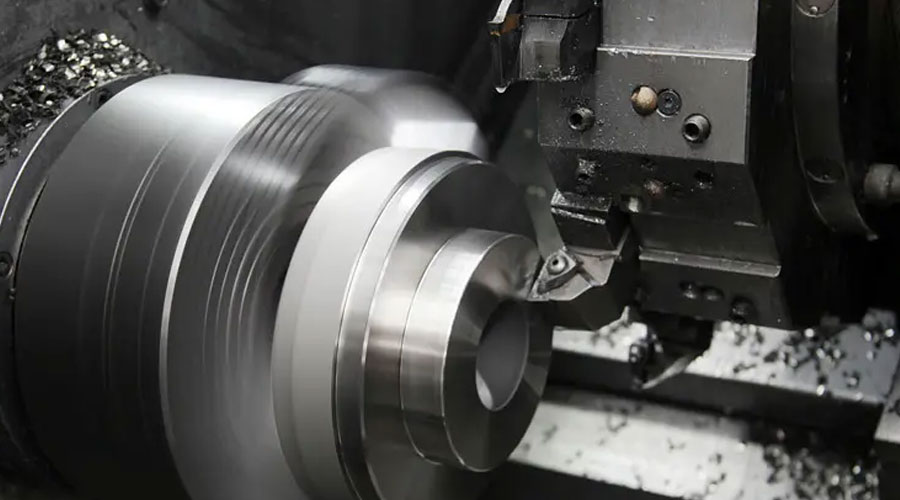

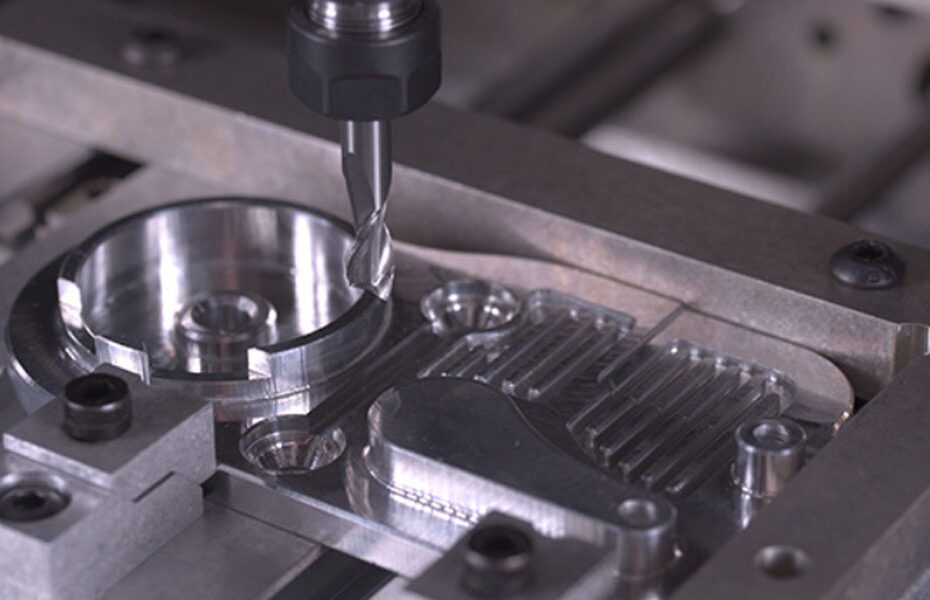

Why Is The Surface Of Stainless Steel Round Tube Not Smooth When Machining?

In the process of machining stainless steel round pipes, cutting is a process worth noting. If you are not careful, some problems will easily occur. For example, some irregular metal formations, adhesions, etc. Surface roughness grades are reduced due to objects or nicks. So, what are the reasons for the uneven surface of stainless steel… Read More »Why Is The Surface Of Stainless Steel Round Tube Not Smooth When Machining?