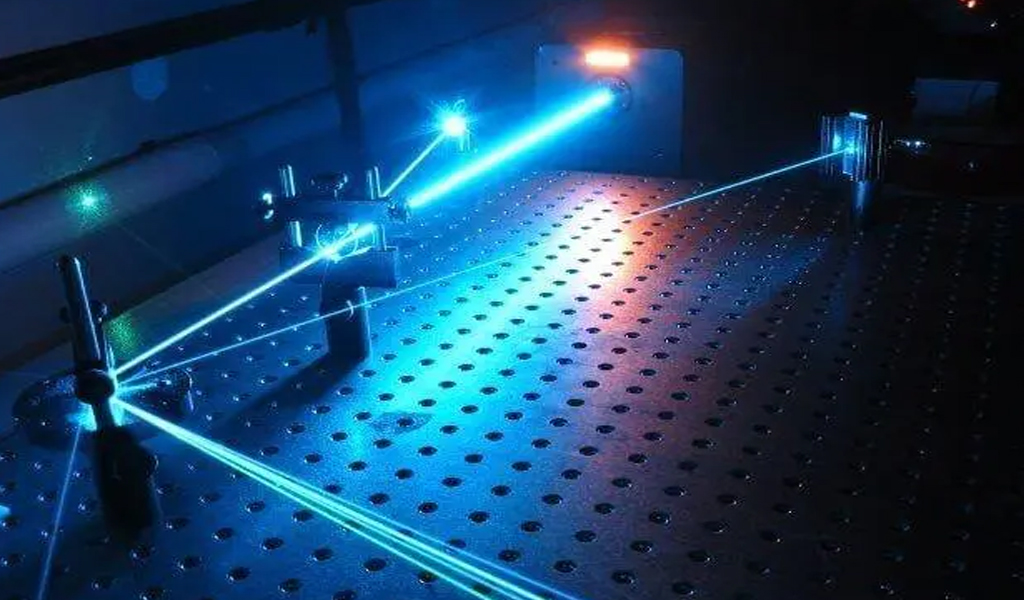

Laser is another major invention of mankind after atomic energy, computers and semiconductors. Laser refers to the light produced by stimulated radiation of atoms, which has the characteristics of high brightness, high directionality, high monochromaticity and high coherence. The good performance of laser makes it have high application value in industry, communications, medicine, military and other fields.

The technical threshold in the field of femtosecond laser fine micromachining is high, there are not many companies involved, and the company has strong competitiveness. The macro-Laser market in the laser industry is relatively large, with a large number of companies participating in the competition. The field of laser fine micromachining has a high technical threshold, started late, and has a small number of companies participating in the competition. Femtosecond laser cutting achieves Laser purposes by interacting with materials through high photon energy or high peak power, which can directly destroy the molecular health of materials in a short period of time and thereby change the properties of local materials.

Han’s Laser, Huagong Technology and other companies are involved in macro Laser and fine micro Laser, so the overall scale is relatively large. Be-Cu Prototype inc has long been deeply involved in fine micro-machining fields such as military industry, scientific research institutes, and medical treatment. The company still has a large gap compared with Han’s Laser, Huagong and other companies. However, in several subdivisions where the company’s products are located , the company’s product scale, technical level, performance indicators, market reputation and other aspects are sufficient to compete with the best domestic and foreign enterprises. Be-Cu Prototype inc focuses on fine micro-machining equipment of femtosecond laser equipment, non-carbonized special-shaped cutting, non-taper drilling, and high-precision fixed depth etching. The equipment is mainly used for ultra-fine cold Laser of curved and complex surface parts, which can be achieved High-precision micro-holes, group holes, etc. below 10um, no burrs, thermal deformation and remelted layers, and no micro-cracks. It can realize microstructure Laser on the surface of metals, non-metals, high-temperature alloys, and composite materials, such as through holes, blind holes, odd-shaped holes, microcavities, special-shaped grooves and other high-quality hole making.

Femtosecond fine micro laser cutting will become an important direction for the development of laser cutting in the future. In the context of the deepening transformation and upgrading of China’s manufacturing industry, product and parts Laser are gradually becoming more precise and miniaturized. Laser technology is also constantly developing towards high power, narrow pulse width, and short wavelength. Higher power can increase the Laser speed. Optimize Laser efficiency. The narrower pulse width of femtosecond laser can reduce Laser damage and improve Laser quality. Shorter wavelengths can produce smaller light spots for Laser, provide higher resolution, and improve Laser accuracy. As ultrashort pulse lasers move towards more mature industrial applications, fine laser micromachining technology will open up a wider range of applications and become an indispensable tool for many industries.